Learn how to service your small eMoto fork to fix your leaking fork seals. In this video we are servicing a FastAce 2.0 fork. You can follow these steps for many other forks. If you are unsure about DIY this project we offer a Fork Service where you can simply send your forks to us and we will service them for you.

Tools and Supplies Needed

- 37mm SKF Fork Seals (1 Set Per Leg)

- 1 Bottle of High Quality Fork Fluid (5wt, 7wt, or 10wt)

- Suspension Cleaner

- 37mm Fork Seal Driver (Optional)

- 37mm Fork Seal Bullet (Optional)

- Flat Screw Driver

- Small Pry Bar to remove fork seal

- Large Adjustable wrench for top cap

- Narrow wrench for set nut (varies by fork)

- Vice with Soft Jaws (Highly Recommended)

Which Fork Fluid to Choose?

| This is the standard weight fluid, choose this if you are under 170lbs and consider yourself an average rider. | 5wt |

| For riders up to 200lbs or more aggressive riders. For the ultimate upgrade choose our custom tune service. | 7wt |

| For heavy riders or big jumpers wanting the maximum dampening. We highly recommend you have your fork custom tuned if you fit this category | 10wt |

Prep on BOTH Fork Legs

- Remove forks from your triple clamps.

- Remove front tire.

- Remove Brake caliper from fork leg.

- Remove any zip ties or other things attached to your forks.

- Loosen top triple clamp bolt.

- Break your fork top cap loose while it's still in the bike and lower clamp is holding it secure. Don't unscrew all the way, just loosen it.

- Loosen bottom triple clamp bolt, hold fork leg it might slide to the floor once clamp is loose.

- Remove fork tube from the triple clamps.

- Clean all dirt and oil off of forks, very important you don't introduce dirt into your fork internals.

- If you choose to ship your forks to have us service your forks you can package them up now. HINT: Take them to a UPS store for professional packaging and shipping all in one stop.

- Open top cap of fork, helps to do this while the fork is still on the bike. Be sure to loosen the top clamp pinch bolt before removing top cap.

- Drain all fork fluid from the fork leg and put the oil into a container that you can take to your local oil recycling facility. You can usually take it to your local auto parts store to recycle.

Brake-Side with Spring Fork Leg Steps (Left)

- Hold wrench on damper tube nut and use large adjustable wrench to remove the top cap from the damper tube.

- Pull the fork tubes apart into two pieces and drain any remaining oil.

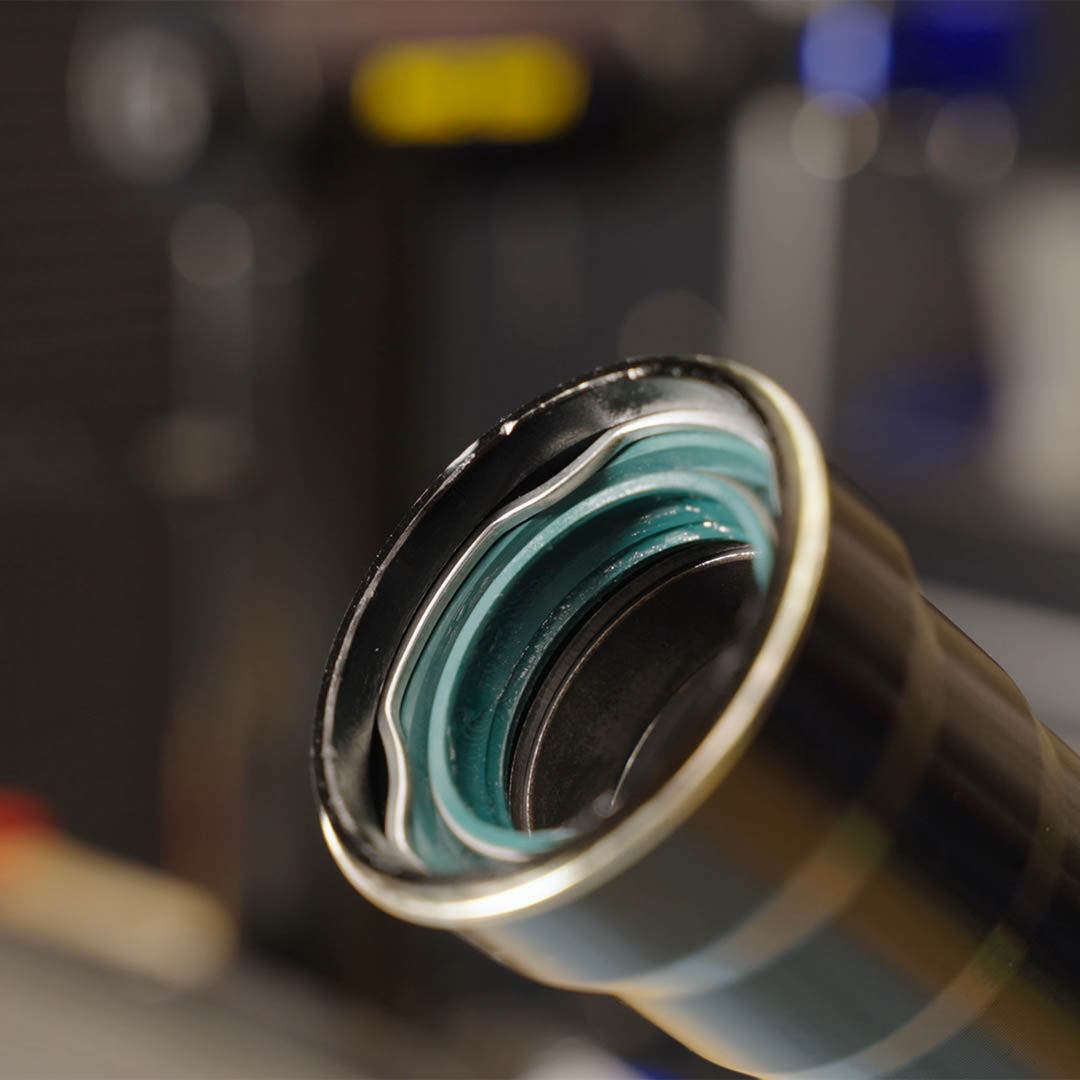

- Remove the Fork Dust Seal

- Remove the retaining clip holding the fork seal inside of the upper tube using a flat blade screwdriver.

- Remove the fork seal using small pry bar, be very careful not to damage the fork tube metal, be gentle and work it loose.

- CLEAN the upper and lower fork tubes with suspension cleaner. Flip the lower leg upside down and compress the rod into the lower spring to force any old dirty oil out of the spring chamber. Keep cycling this until the oil is out.

- Press the new fork seal into the tube using your fingers with the metal tension spring facing down (outside). If you have a fork seal driver you may use it to install the seal.

- Insert the retaining clip into the groove on top of the seal.

- Insert the dust seal, metal tension spring facing out.

- Apply a small amount of suspension slick grease to the inner seals. If you don't have any apply new fork fluid to the seals.

- Insert lower fork leg into upper leg being careful to not damage the seals.

- Pour 150ml fork fluid into fork, be careful to support the lower leg, it can fall out if not supported and spill your new fluid everywhere. If you find it easier skip to the end and pour the fluid in after the fork cap is secured to the damper rode, the fork cannot come apart at this stage.

- Screw top cap onto damper rod until it bottoms out.

- Tighten damper nut onto fork cap.

Non-Brake Damper Side Fork Leg Steps (Right)

- Hold wrench on damper tube nut and use large adjustable wrench to remove the top cap from the damper tube.

- BE CAREFUL of a tiny screw under the top cap, don't loose this. Pay attention to the orientation of how it is positioned.

- Pull the fork tubes apart into two pieces and drain any remaining oil.

- Remove the Fork Dust Seal

- Remove the retaining clip holding the fork seal inside of the upper tube using a flat blade screwdriver.

- Remove the fork seal using small pry bar, be very careful not to damage the fork tube metal, be gentle and work it loose.

- CLEAN the upper and lower fork tubes with suspension cleaner. While cleaning fluid is inside the lower fork leg cycle the damper up and down to bath it in the solution and break free the factory oil and any dirt. Do this over and over until the cleaning fluid comes out clear.

- Press the new fork seal into the tube using your fingers with the metal tension spring facing down (outside). If you have a fork seal driver you may use it to install the seal.

- Insert the retaining clip into the groove on top of the seal.

- Insert the dust seal, metal tension spring facing out.

- Apply a small amount of suspension slick grease to the inner seals. If you don't have any apply new fork fluid to the seals.

- Insert lower fork leg into upper leg being careful to not damage the seals.

- Pour 300ml fork fluid into fork, be careful to support the lower leg, it can fall out if not supported and spill your new fluid everywhere. If you find it easier skip to the end and pour the fluid in after the fork cap is secured to the damper rode, the fork cannot come apart at this stage.

- Insert the small adjuster screw back into the damper rod and screw it into the rod a couple turns.

- Screw top cap onto damper rod until it bottoms out. Be sure that the clicker freely turns and you can feel/hear the adjuster clicks to verify the adjuster aligned properly with the small screw you inserted into the damper rod. It's possible to misalign this and the cap not screw all the way onto the damper rod. Be sure you have this working properly before tightening the damper nut onto the fork cap.

- Tighten damper nut onto fork cap.